2016 MHA Annual Meeting

Combustion Testing Workshop

MHA Technical Committee,

with special thanks to Carsten Homstead and Boris Kukolj

Back

to Wildacres 2016 Photo Report

Skip to Test Results

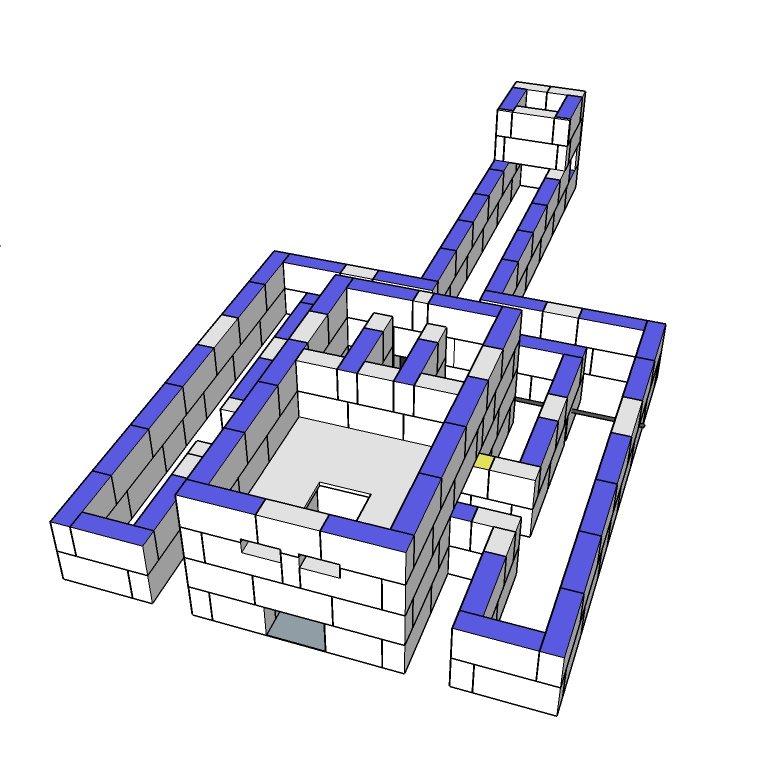

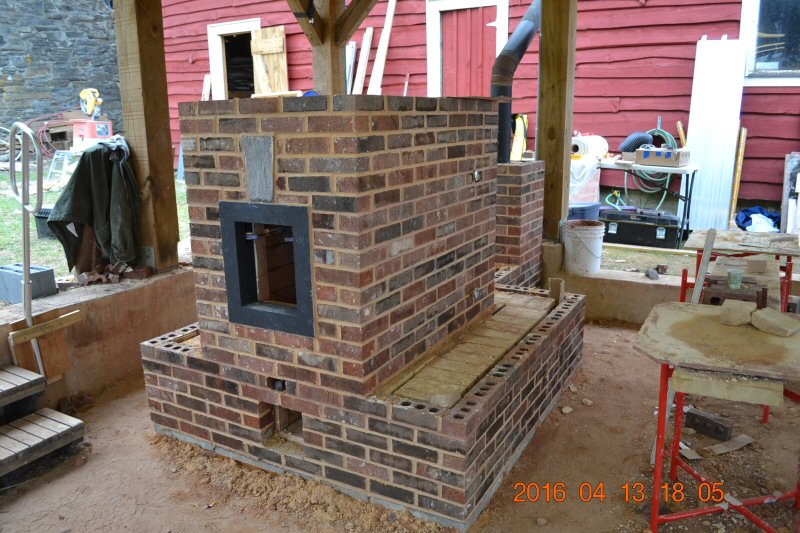

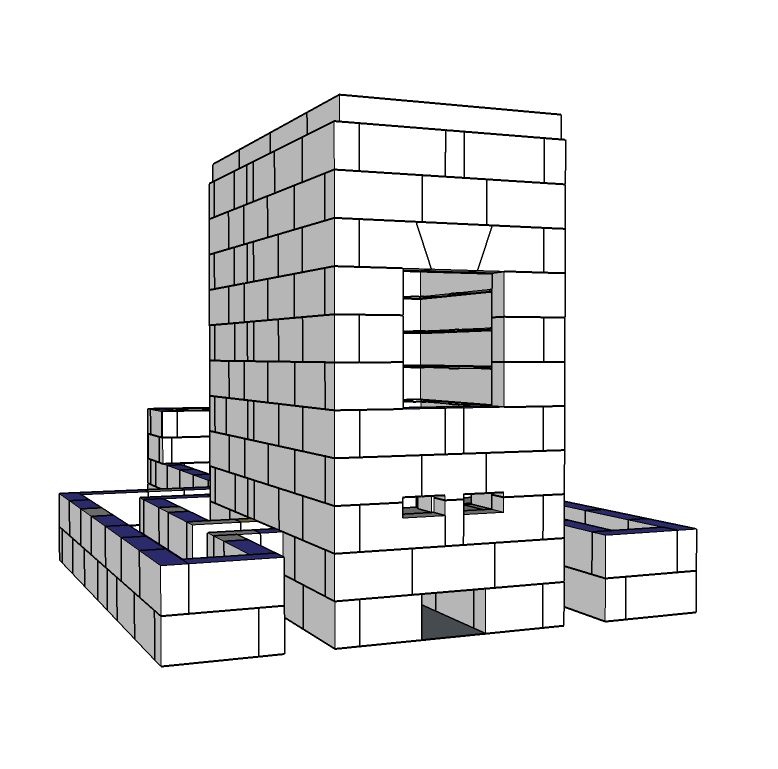

Heater

is a single

bell, with wraparound heated bench that joins at the remote rear

chimney. There is a bench bypass for cold starts.

Chimney

is at the bottom of the photo. Heater was a one-off design by Carsten

Homstead,

designed

to provide heated seating for the pizza party, and to demonstrate a low

height

single

bell with an Austrian spec eco-labelled firebox.

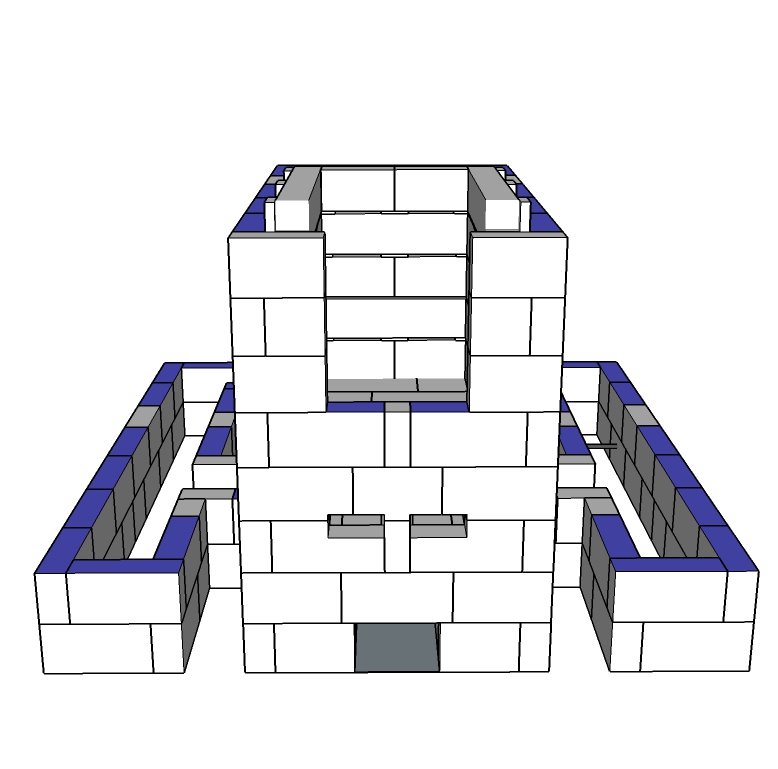

Course

5

Hammer

sits on top of a cast iron bypass damper to bypass the bench for cold

starts.

The

heater did prove a little slow to start when it was fresh. It was very

hard to get a temperature reading much above ambient in the

benches,

with the bypass closed. Even at full burn, you could put your hand on

single wall chimney connector pipe.

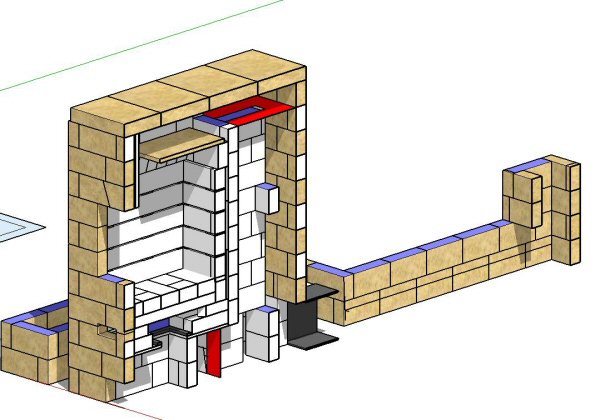

Arrow

shows spacer strip with ceramic paper corner gasket. This creates a gap

for the air supply to the horizontal air slots

in

the firebox. The gasket is an expansion joint, used at the inside

corners.

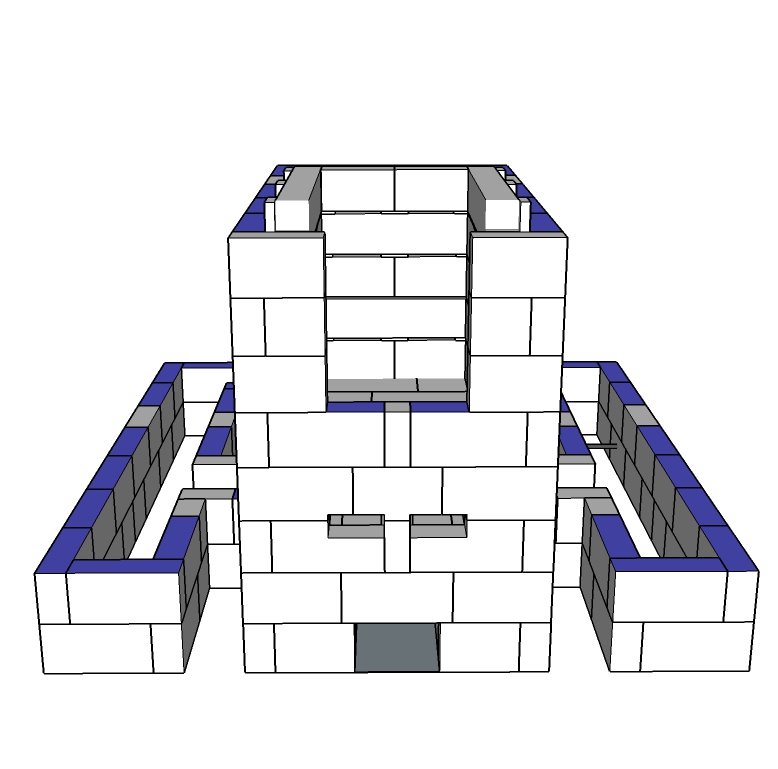

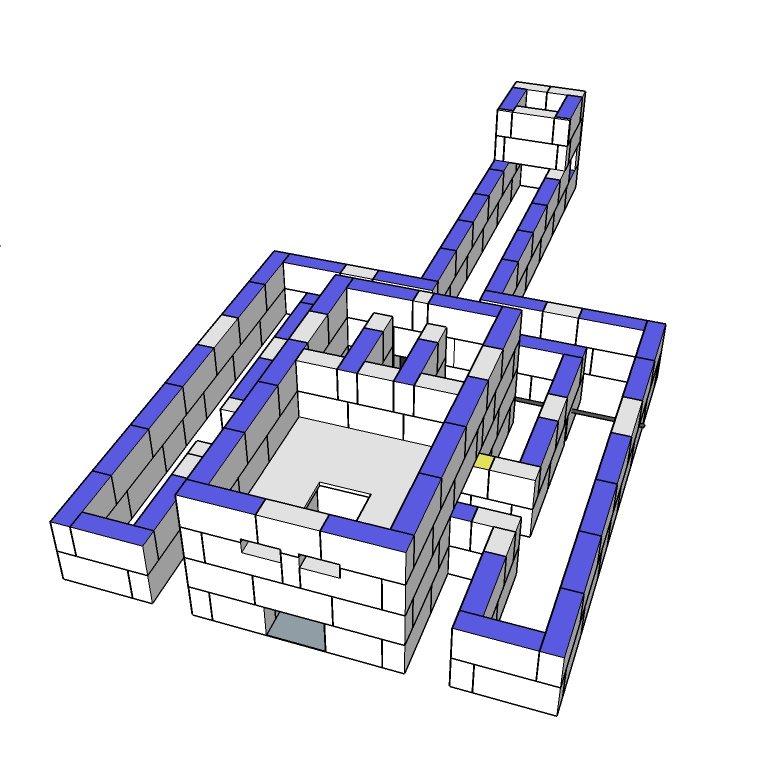

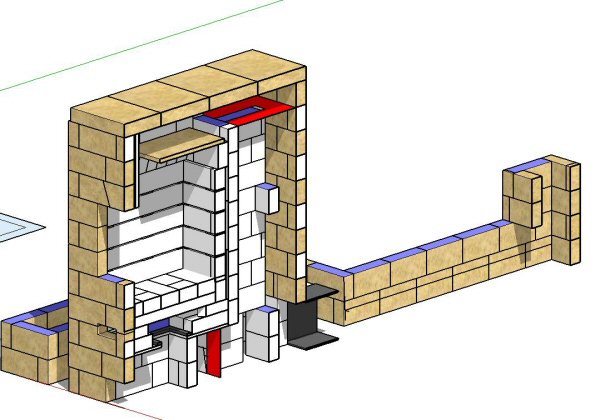

Single

downdraft heat exchange section behind the firebox. The interior bricks

in this "bell" provide extra heat exchange surface.

Course

8

Note

the cardboard expansion joint at the corner, between the firebrick

heater core and the clay brick facing.

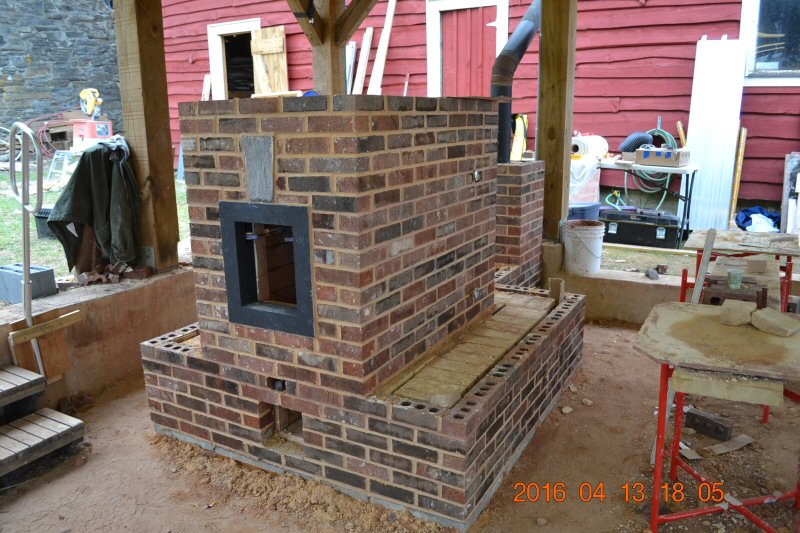

This

heater needed to go up fast, to get ready for testing. MHA's has some

very seasoned production brick masons

that are ready when needed.

The

Frisch gang.

Interior

baffle will be just beneath the firebox ceiling. Gases from the firebox

exit towards the front (top of photo).

Bench

is designed to be cappable with regular 9" firebricks.

Course

13

Matt

Helicke tools his joints. The mortar is Goldart fireclay and sand.

Cardboard

wrap for heater core.

Side

Section

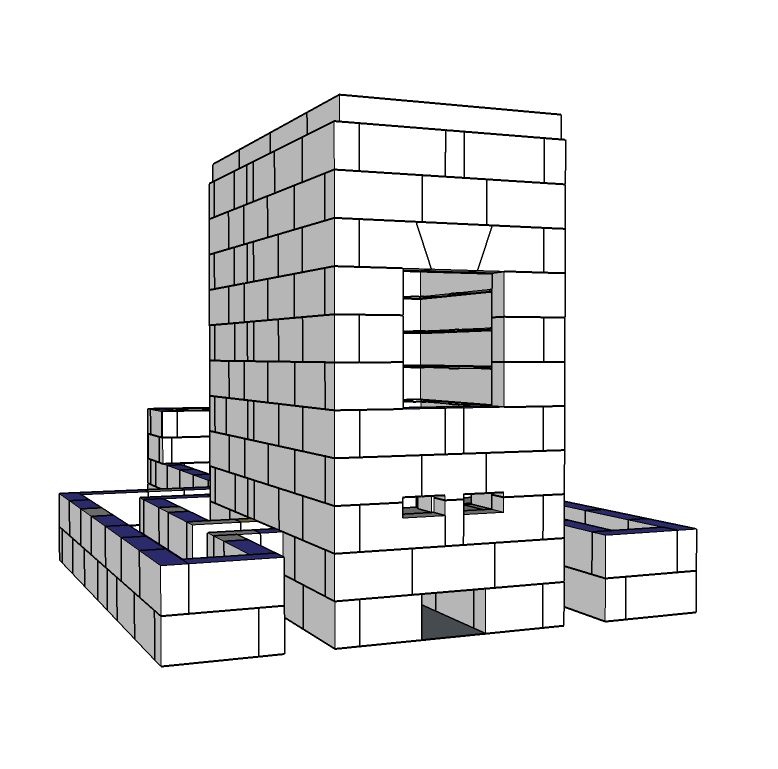

Installing

the firebrick tile ceiling slabs.

Finishing

the brick section of chimney.

Custom

airframe for firebox door.

When

curing the heater, there was a very large temperature drop in less than

30" of downdraft, on the order of 150 degrees F.

This

difference became less as the bricks got saturated with heat.

Running

up the brick facing. 1:45 PM

3:00

PM.

Chimney

transition to single wall 6" connector pipe.

Installing

the chimney.

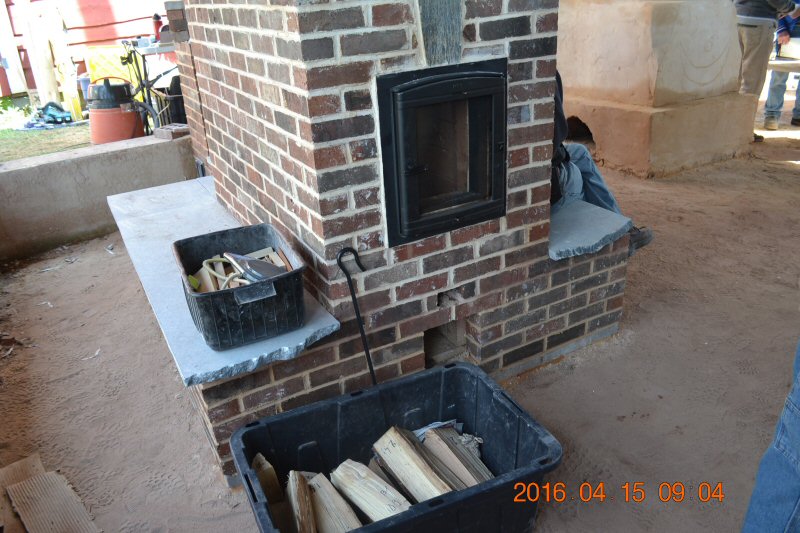

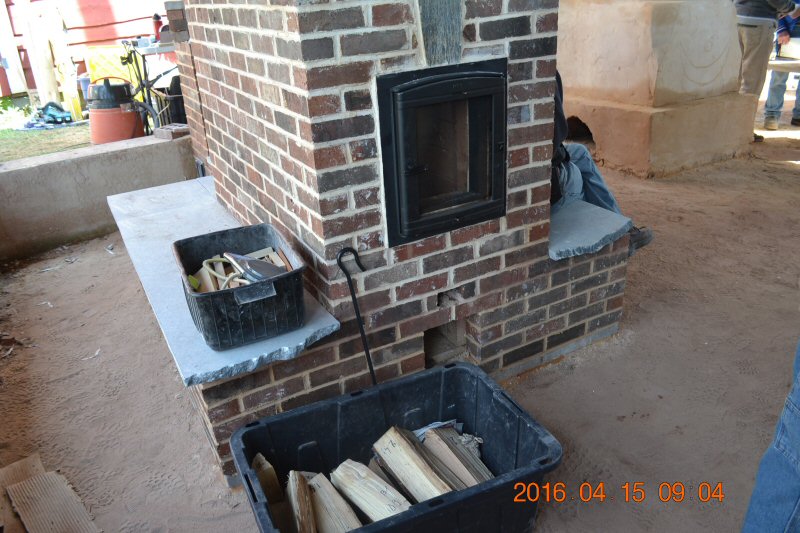

Alberene Soapstone donated

several large soapstone slabs that were cut up for bench tops and

capping stones.

Door

install into the airframe.

Day

1, 10:00 PM - Lighting the curing fire.

One

hour later.

Day

3, 8:00 AM.

Fire

has been burning all night. Note some of the lightened mortar joints,

where the bricks are starting to get dry on the outside.

A

bit more drying can be seen.

Reload

on the curing fire.

Shortly

after the start, the plume from the stack is mostly steam.

A

very faint residue is visible after the steam evaporates.

Almost

pure steam

Cutting

out the soapstone slabs for the bench tops and heater cap.

Installing

the soapstone bench tops.

More

drying is evident.

First

test run. Heater was still warm (390F firebox temperature) from the

overnight curing fire.

Test Results

The

first run was very good, considering it was a partially cured heater.

For

the second run, the combustion air had been left closed overnight,

which allowed moisture to migrate back inwards.

There

was lots of water in the stack, and the stack temperature was 40

degrees lower. As a result, PM was fairly high for an eco-firebox.

Run

three was good, with extremely low CO, PM under 1 g/kg, and overall

efficiency over 80%. In pellet stove testing Condar efficiency

has

generally been 1% - 3% lower than calculated B-415 efficiency.

Calculator tuning:

Test 1:

Calculated

flue gas temp @ heater exit @ peak of burn (lowest O2 point) : 238F

Actual

temp : 227F

Test

2:

Calculated

exit temp @ peak : 178F

Actual

: 177F

Test

3:

Calculated

: 210F

Actual

: 223F

Saturday

morning, a couple of hours after the finish of the pizza party.

Heater

was still hot, which makes for a difficult demo later in the morning.

See also:

2015 Photo

Report

2014 Photo

Report

2013 Photo

Report

2012 Photo

Report

2011 Photo

Report

2010 Photo

Report

2009 Photo

Report

2008 Photo

Report

2007 Photo

Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This

page was last updated on June 6, 2018

This page was created on April 22, 2016

Back

to: