| Gallery | The Mall | Member Directory | MHA News | Bookstore | Library | Links | Lopez Labs |

2000 MHA Annual Meeting - April 15 - 22

at Wildacres Retreat,

Little Switzerland, N.C.

Photo Report by Norbert Senf - Coming soon: Report by Jay Hensley

1.) Driving Down -

visit to Old Salem, NC

2.) Setting Up

3.) First Session

4.) Bricks and Mud I: Clearances to

Combustibles Testing

5.) More Meetings

6.) Bricks and Mud II: Pizza Oven

7.) Clearances to

Combustibles Testing

8.) Bricks and Mud III: Hands on

Certification Tests

9.) Pizza Time !

Ron Karson and I left from Mississauga, west of Toronto, on

Friday April 14

Ron is a stone mason from Ontario who is interested in heaters

and bakeovens

On the previous Tuesday, we had both attended the ASTM meeting in

Toronto,

followed by a heater core installation in Mississauga.

In North Carolina, we stopped at Old Salem. Here Ron checks out

the workmanship on a stone wall. The large building is the

Winkler Bakery

built in 1800. The attached small roof houses the bakeoven.

Old Salem was settled by Moravians, who were Protestant

Germans from Czechoslovakia. They are still well-known for

their pottery. Shown is an original coal burning Kachelofen,

located

in the Single Brothers House, which was built in 1769.

Woodworking shop in the Single Brothers House.

Detail of the tool used to cut threads in wood, such as for a

woodworker's vise.

Pewter shop. The melting pot is located in the fireplace. The

castings are finished by scraping and filing by hand, and sold in

the giftshop.

Reproduction of an early stove. The tiles are slip cast

in plaster molds. Note the damper detail.

Damper detail - custom terra cotta tile.

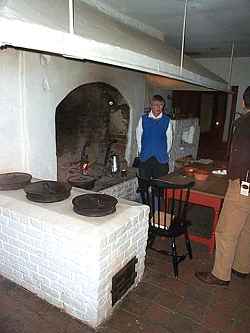

Main kitchen. Cookstove (not visible) at left, cooking fireplace

in centre, bakeoven on right. Note smoke hood over fireplace.

Cookstove. The cast iron pots are quite deep.

Note location of firebox door.

Interior of bakeoven. Gases exhaust at rear, near bottom.

Larger domestic bakeoven. Gases exhaust at rear, and are routed

back

over the top of the oven, and exhaust into a regular chimney. Dan

Fisher, who

we met a few days later at the MHA meeting, told me that the

Amish call this

a "squirrel tail" oven.

Fireplace in a barn. Note the 90 degree twist in the

chimney.

Typical heavy timberframe construction with masonry infill.

Interesting window sill detail.

After meeting at an airport hotel near Asheville the previous

day,

a number of members drove to Tom Trout's place near Wildacres to

get materials for the upcoming bricks and mud sessions. Ben

Sotero,

Ron Karson, and Jerry Frisch check out the interesting bits and

pieces.

Interesting!

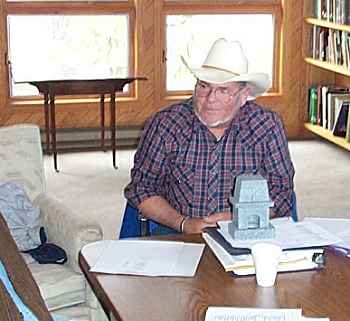

Ernst Kiesling came from Nova Scotia for a full day's

presentation

on the Austrian system of Kachelofen calculations that he

developed.

Relaxing after the first day's sessions on the patio overlooking

the

Smokey Mountains.

We shared the dining hall with a group of lapidary enthusiasts

(jewellers).

Ben Hurd, Albie Barden, and Jerry Frisch start building the

heater

for clearances to combustibles testing.

Pat Manley starts on a bakeoven while Ben Hurd and Gary

Hart mix clay/sand mud.

Rod Zander and Albie Barden study Jerry's technique.

Ron Karson lays up the 8" soapstone left firebox wall.

Albie Barden works on the 8" brick right wall. The rear

wall is 4.5" firebrick.

Pat Manley presents Jerry Frisch with one of his handcarved

soapstone heaters in recognition of Jerry's donation to MHA's

fundraising campaign.

Jerry with his new heater

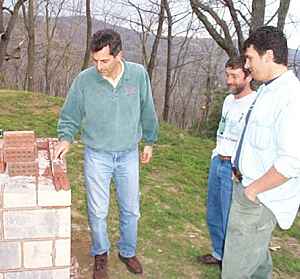

Pat Manley builds the base for the pizza oven. Tony Cuoco

and Marty Pearson help out.

Pat talks about oven construction as Tony Cuoco, Walter Kelly,

and John LaGamba listen.

John LaGamba demonstrates his trowel technique to Tony

and Walt.

Pat Manley, Tom Trout, and Ben Hurd.

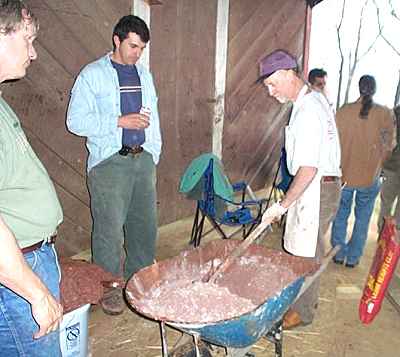

Albie demonstrates clay mud mixing.

Ron Karson gives John LaGamba some tips on bricklaying

as a livelyhood.

The oven progresses. Peter Solac and Mary Pearson help.

View of the precast oven arch. Ben Sotero, Dann Carnes and Peter

Solac listen to Pat.

Detail of flue run above oven. This photo was taken during

teardown, just after

the flue liner was removed. A permanent oven would have had

insulation around

the bake chamber.

Would you really want to mess with these guys?

Dann Carnes and Albie Barden watch the curing fire.

Weather on the mountain top was quite changeable, as

the attire indicates.

The 8" soapstone test panel is visible. It is isolated from

the

back wall by a strip of insulating board.

Curing fire in the bakeoven. Heater is visible in the background.

Ron Karson and Jerry Frisch with point-and-shoot infrared

thermometers.

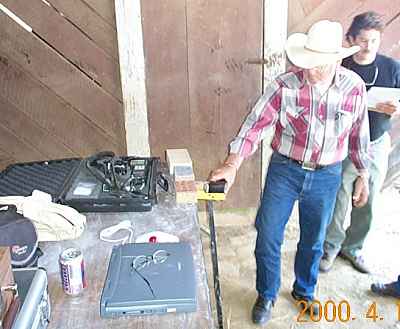

Lopez Labs field setup. Jerry reads the ambient surface

temperature

of three different bricks. Combustion analyzer is in the black

case at

rear. Laptop computer in front. Also present are a wood moisture

meter,

digital camera, and thermo-anemometer.

Ron Karson records readings. The 8" soapstone/brick

clearance comparison was quite interesting.

Check out the results.

Ben Sotero takes a surface temperature reading.

The infrared thermometer is point-and-shoot, and

tales a reading instantly.

Pat Manley was on the fuelling documentation team. Every piece

was

weighed and measured for circumference with a cloth tape (this

provides surface to volume data).

Each fuel load was documented photographically.

First load stacked in the firebox.

Ready for a reload

Pat Manley reloads. The first test consisted of 4 back-to-back

burns of 50 lbs each (200 lbs total). We helped ourselves to

Tom Trout's primo stash of seasoned hardwood (Thanks, Tom). Fuel

moisture was 14%.

Weather during the first test was sunny and calm.

Marty Pearson checks the flueliner, which was running at

about 500 F on the surface.

Relaxing after a strenuous session of temperature taking.

Ron Karson and Rebecca Carnes perform a flue gas analysis as

Dan Fisher looks on.

In the evening, Pat Manley gave a slide presentation on his

recent stovebuilding trip to Guatemala. It was very moving.

There are some more details at

http://mha-net.org/docs/v8n2/pat02.htm

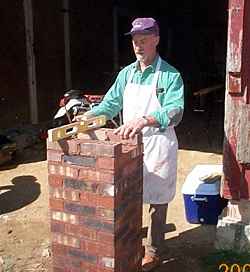

Marty Pearson builds a section of brick chimney for the practical

portion of

his MHA Heater Mason

Certification.

Albie Barden does his hands on test.

The pizza oven after a second charge is burning down.

Just about ready.

Tony and Bev prepare the toppings.

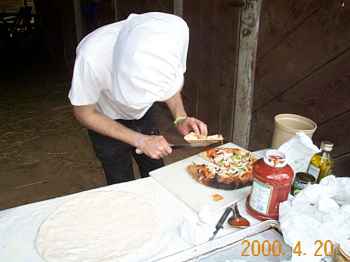

Wildacres' chef Thomas Broadway was hired to do the honors. He

had

never baked in a brick oven before, and was very impressed.

Gavin Custer snaps a picture.

Pat checks the oven with some cornmeal. The first handful

spontaneously burst into flames --- too hot.

The first pizza goes in. Tom Trout had prepared 12 pizza shells

ahead of time.

Looking good.

Smelling good.

Thomas checks the crust on the first pizza. We ate 11

pizzas between lunch and dinner. As John LaGamba pointed out, we

only spent 3 hours out of the whole day not eating.

A keg of Heiniken arrived just in time.

Pizza party. A pizza oven is a natural social focal point.

Tearing down.

See also,

1999 Photo Report

1998 Photo Report

1997 Photo Report

![]()

This page last updated on

October 12, 2009

This page created on April 25, 2000