2013 MHA Annual Meeting

Dreischaliger Grundofen

Austrian Triple Skin (Air Gap) System

Back to Wildacres 2013 Photo Report

Finished heater in curvilinear multi-colored, multi-textured plaster.

Opposite

side with wooden bench. The plaster on this side has been marbled with

a second color, and then burnished to a high gloss

Alex Chernov, Paul Polatschek and Stefan Polatschek.

Alex arranged for the Austrian team to visit Wildacres and demonstrate the Austrian air gap free-form Kachelofen

construction system. Paul is a master stove fitter. Paul and Stefan led the Austrian team. It resulted in an extremely valuable

exchange of stovebuilding cultures from several continents.

Jerry Frisch and Luis Wegscheider. Luis is the head design consultant for Ortner. He is 28 years old.

Preliminary plans. Actual plans are different, because of the difference in materials from Austria.

An updated set wil be posted when available. Check back to this page.

Full size template is printed on a large plotter, directly off a 3-D CAD model. This allows layout of things like fittings,

electrical, etc. to be placed precisely and saves the stove fitter a lot of time.

The heater outline is transferred to the foundation.

Outside air inlet. Normally, it is fitted with an airtight damper. Sometimes, with an electronic control.

Cantilevered angle irons for the wooden bench.

Outside air inlet into the firebox, beneath the firebox floor.

Ortner brick and tile cutter. Combined with a special gap-filling mortar, it greatly reduces the number of saw cuts.

Firebox floor tile. Note the air gap around the edges for combustion air.

Air gaps are temporarily stuffed with empty mortar bags.

Ortner Haftmȍrtel. It is mixed in small quantities

Amazing stuff. Gap filling, sets in 20 minutes, bond is stronger than the brick

Allows free form construction, as you will shortly see. Good to 1000C.

Data sheet for Haftmȍrtel

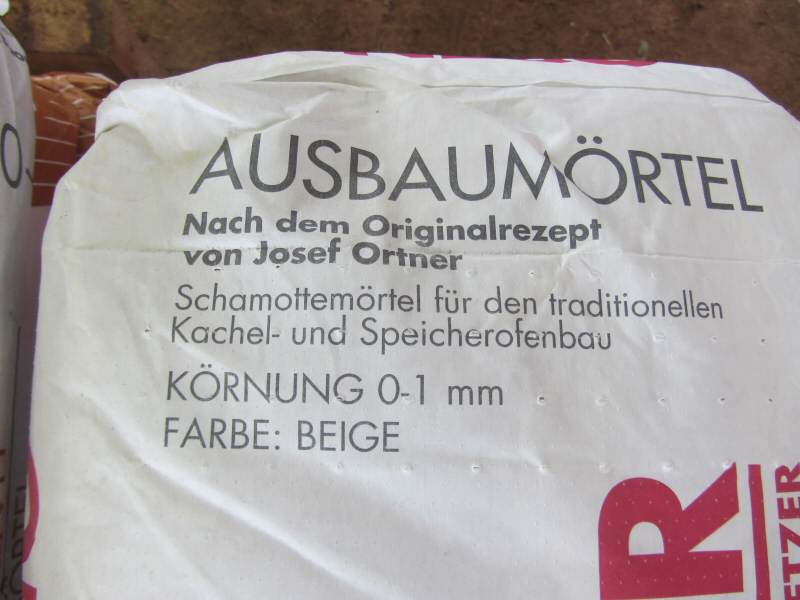

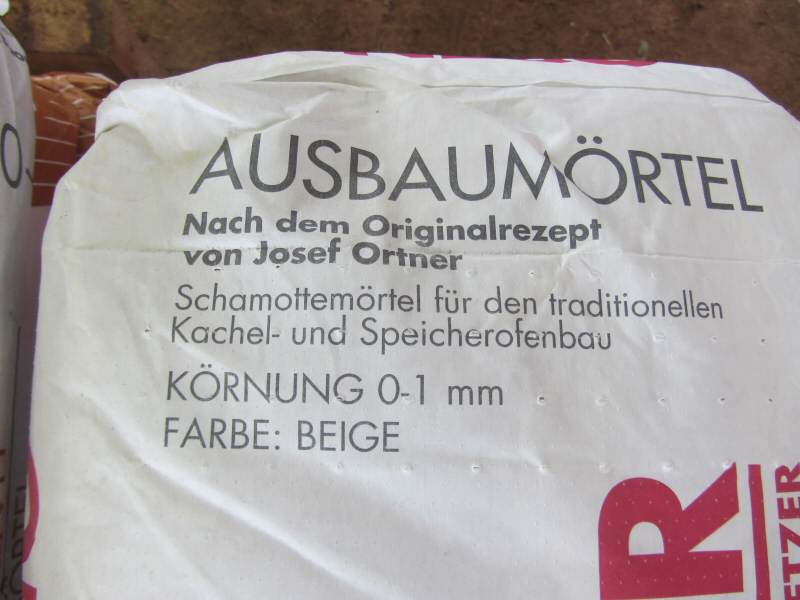

Data sheet for Ausbau Mȍrtel (clay mortar for firebox)

Ortner product catalogue.

Trial fitting the door frame.

Demonstrating the new Ortner precast firebox modules.

The were developed by Luis Wegscheider, including building the Autocad Inventor

solid model that was used directly to program the CNC cutting tool for the molds.

In the background, pails of Ortner Feuerbeton 2200 castable refractory.

This is the material that the bricks are cast from. Luis cast a demonstration piece for us.

The castable was almost liquid and required little if any vibration. It was ready for

demolding in one hour. Price in Austria is similar to castables here.

The ingenious knob-and-socket system allows quick dry stacking.

Knobs at the back establish spacing for air.

Depending on how the knobs are staggered, you get either a no-air-gap joint, or an air gap horizontal joint.

From briefly testing the castable, it seems bulletproof, but the firebox is easily replaceable.

Castable test late at night. It has to be fired to 600C to achieve a ceramic bond and full strength.

Detail

Starting the channels

Carol Pineault from Feu vert

Inside door detail. Protection for the metal.

Clean outs for the channels.

Spacers to create a gap for the combustion air, which is fed about 1/3 up the firebox, all the way around.

Note that the strips are glued directly with Haftmörtel, with no chance for failure. The bond is stronger than the brick.

Luis Wegscheider

Demonstration of firebox construction without the special Ortner bricks. This firebox was burned, then the

bricks were removed and exchanged for the Ortner bricks.

Corbelling out for the ceiling tile.

Note the combustion air supply gaps in the firebox walls.

Note the corbels which will support the floating ceiling tiles.

The throat will be located at the front.

This is to allow good mixing of the gases and prevent short circuiting of the air towards the exit.

Upper ceiling tile rests on ceramic blanket, forming a horizontal channel with the lower tile.

Throat is at the front, just above the door.

The door was double (insulated) ceramic glass, without air wash. It stayed completely clean.

Showing firebox air system and ceiling tile with throat at the front.

Air is introduced all around, in the bottom 2/3 of the firebox, except for the space below the loading door

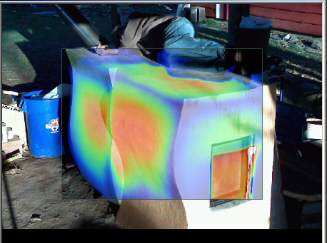

Heater is being fired to dry it out.

At the moment, this is a double skin heater.

The third skin will be added to create the air gap system.

Starting the thin outer shell.

Haftmörtel makes this type of construction possible using splits.

Morter sets up in 20 minutes, bond is stronger than the brick.

Good gap filling, so precise cuts are not needed and bricks can be hand cut on a splitter.

Strips of firebrick splits are laid up free form with Haftmörtel.

There is no regard for brick bond (staggered joints)

The open time is about 20 minutes, depending on temperature.

Method for laying out a curve.

Note the stacked joints.

In order to create beams to bridge the facing above the core, firebrick splits are laminated

with Haftmörtel and special pencil wire (Hafnerdraht).

Splits are laminated together with Haftmörtel to form beams.

During demolition, they withstood the load of 15 people standing on them.

Plastering materials.

There is a base coat with mesh, and a colored top coat.

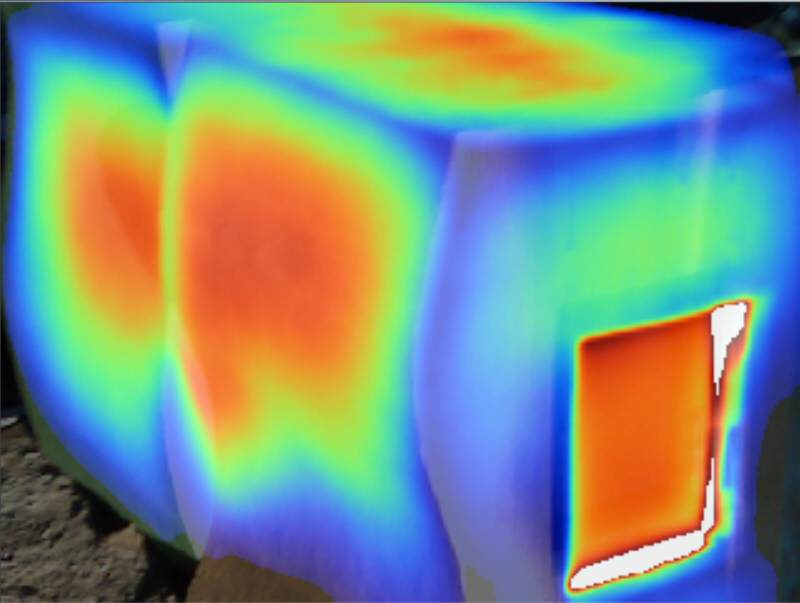

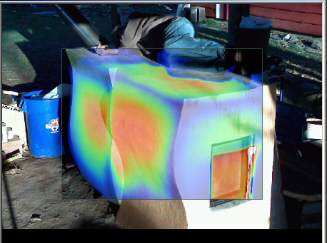

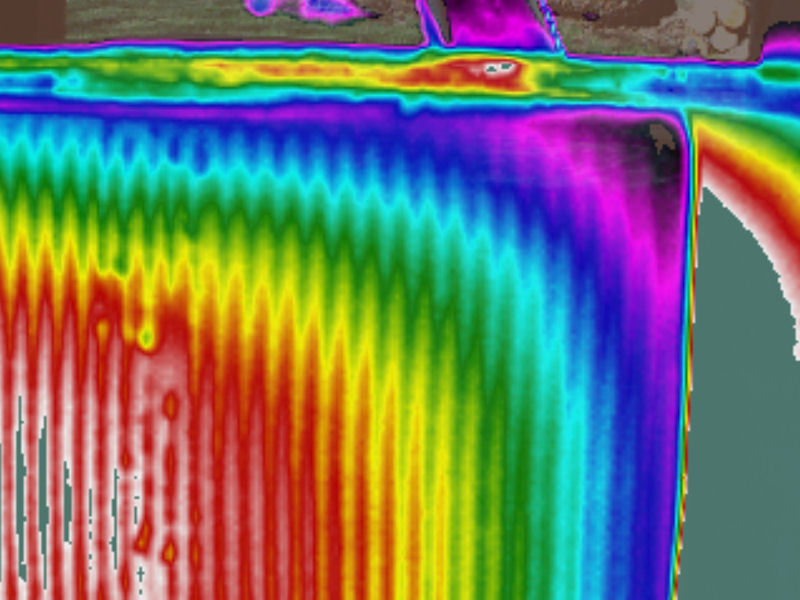

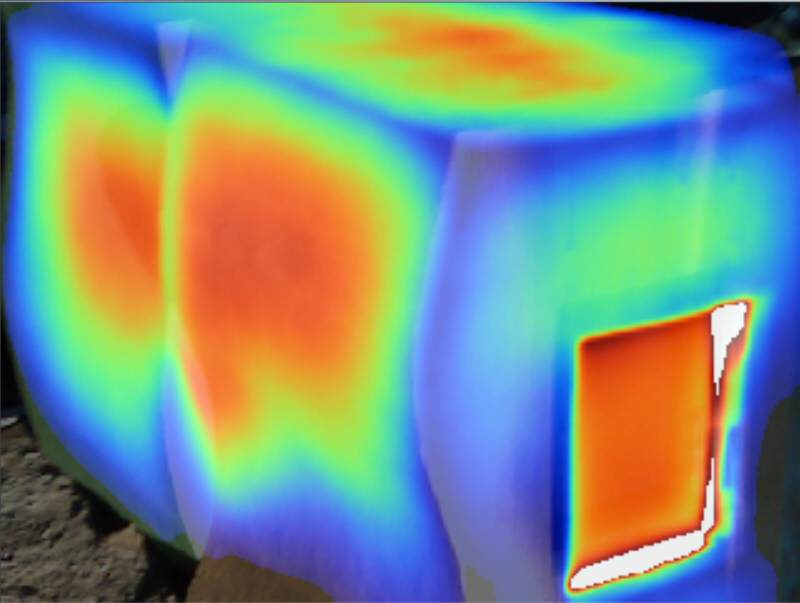

Thermal image of the heater with the base coat of plaster on.

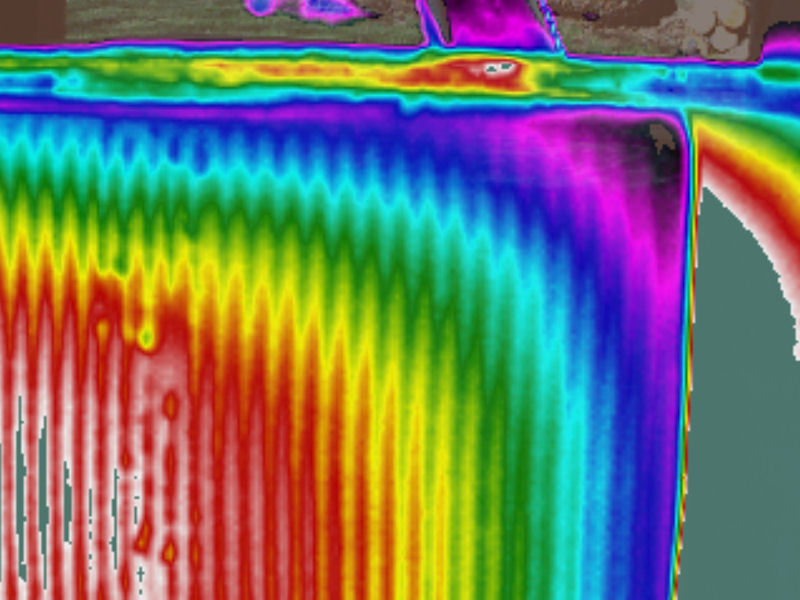

Alex Chernov of Stovemaster, uses a notched trowel to create a verticl ribbed texture.

Alex organized the workshop, the travel for the Austrians, and the delivery of the

materials from Ortner to his shop in Ontario. He generously donated the freight cost

for shipping it to Wildacres, as well as the large ceramic tiles.

Thermograph of the ribbed plaster

Paul Polatschek burnishes the finish plaster to a glossy shine.

Special thank you to Ortner for donating over $2000 of materials to the Grundofen project.

In addition, Ortner made a generous auction donation.

Firebox mortar.

Haftmörtel

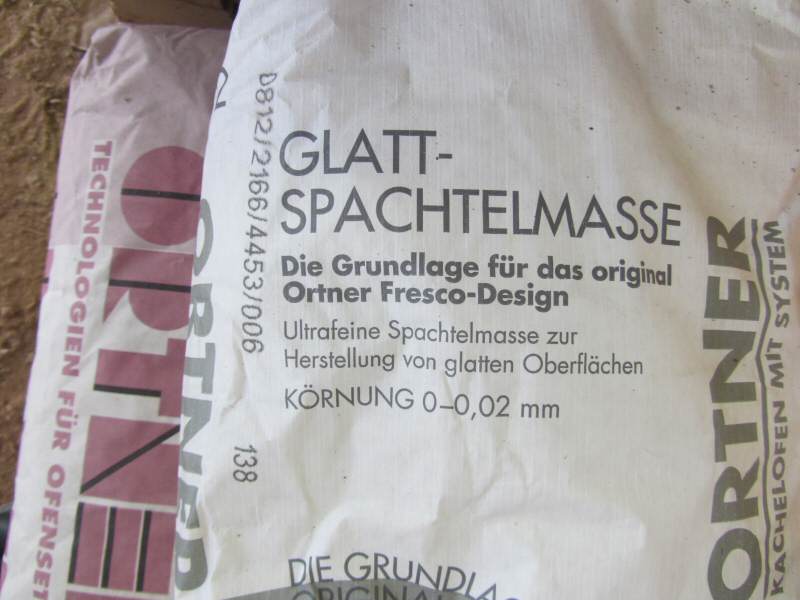

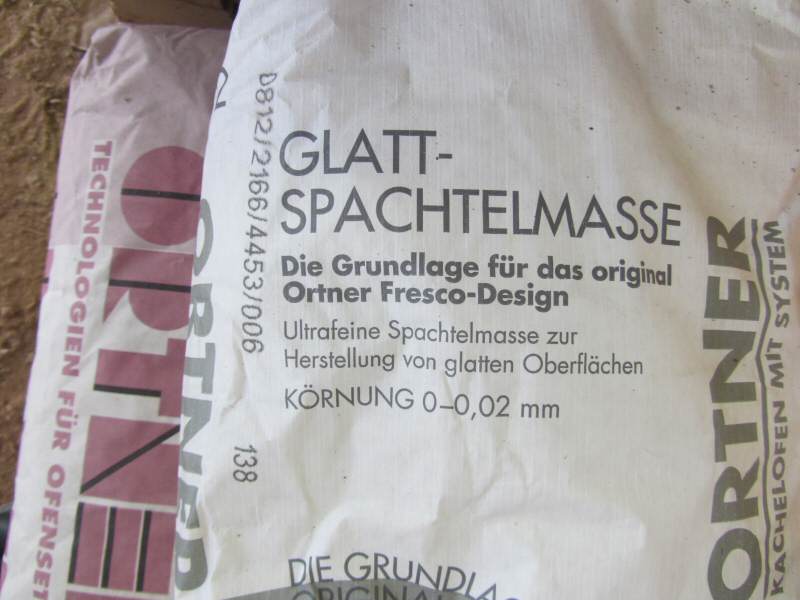

Smooth finish plaster and fresco base

Fireclay castable

Hafnerdraht.

Spring steel rods for making clamps to hold Kacheln together

Fresco

"Mixing liquid"

Wildacres 2013 Photo Report

See also,

2012 Photo Report

2011 Photo Report

2010 Photo Report

2009 Photo Report

2008 Photo Report

2007 Photo Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page was last updated on September 26, 2016

This page was created on April 28, 2013

Back to: