2015 Ontario Stove Testing Camp

July

9 - 10, 2015

with Crispin

Pemberton-Pigott

photo

story by Norbert Senf

Back to Lopez Labs

The

camp took place at Burt's Greenhouses near

Kingston ON.

This

is the shed that holds the 1.25 Megawatt chip fired boiler system.

Attendees

came from as far away as New Mexico and Norway

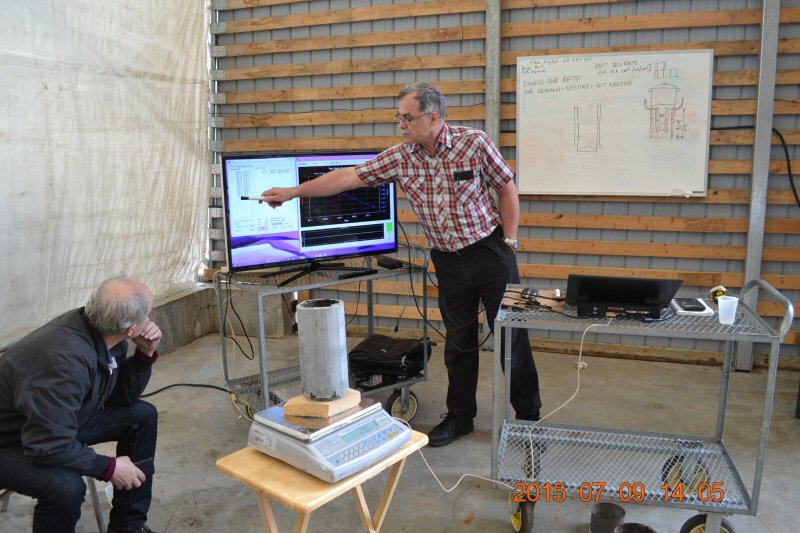

Alex

English, who runs the boilers at Burt's, introduces Crispin

Pemberton-Pigott from New

Dawn Engineering

We

started with a live burn to demonstrate the concepts of a natural

draft, top-lit updrafting gasifier (ND-TLUD)

In

this view the stove is upside down, showing the primary air inlet beneath the fuel bed.

The

burn chamber sits inside an outer sleeve that is used to preheat the

secondary air.

Secondary

air holes at the top. Notice the initial long flaming of the wood gases.

As

the wood burns down to char at the bottom, the flaming is shorter and

happens at the secondary air inlets.

A

restrictor to prevent cold air downdrafting in the tube.

An improved stove that Crispin designed for Mongolia to burn the local lignite coal, achieved a particulate emissions reduction of 99.9%,

A stove changeout program reduced the heavy air pollution in the Mongolian capital of Ulaanbaatar by 65%

MHA

member Andrew Brunning attended the workshop, and brought down this

precast rocket firebox.

A

$1.00 stove developed by Crispin for Haiti. It is sitting on a digital

scale that measures the weight loss from the fuel in order to

determine

the burn rate and power output in real time.

To the left is Jan Sorensen from Norway, who manufactures stoves in Zambia, and is involved in a biochar project there.

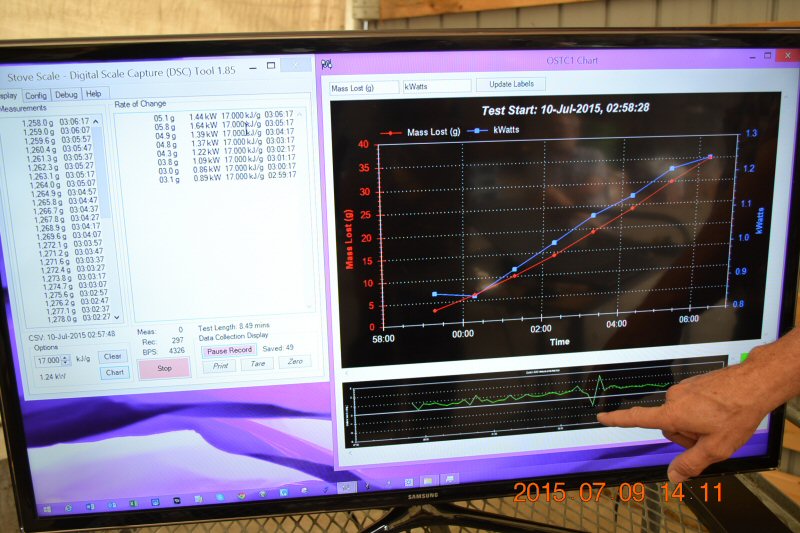

This

custom software takes data from the scale and converts it for stove

testing use.

Notice

the flamelets at the secondary air holes.

Lighting

another TLUD stove, burning pellets. The 4" pipe is used to accelerate

the draft and help get the pellets lit.

The

bottom of the pipe is touching the pellet bed, drawing air through the

pellets from underneath.

Alex

English shows the Condar portable dilution tunnel that he made many

years ago after a visit to Lopez Labs.

He

has done much innovative research into commercial biomass greenhouse

heating, and has worked closely in the past with

CANMET,

the Canadian government combustion laboratory.

Terrence Sauvé examines densified brickets that Alex has experimented

with. On the right is Brian Burt, the owner

of

the greenhouse operation.

Terrence

is an engineer working for the Ontario Ministry of Agriculture,

consulting on farm scale biomass systems.

In

the black shirt is Nathan Jones, who is a field engineer for Combined

Heat and Biochar, with ClearStak

He

is demonstrating the Wohler real time particulate emissions analyzer.

Second from the left is Julien Winter, a soil scientist who is involved in a biochar project in Bangladesh.

Julien prepared this

summary of his recent TLUD research.

Terrence Sauvé chats with Lance Grace, who is an aeronautical engineer and the

principal at Clear

Skies Unlimited

This

is an experimental gravity feed pellet stove that Alex English built,

and hooked up for a demo.

It

needs no electricity. The sprocket in the front is connected to a

manually operated shaker grate.

This

is another prototype without a shaker grate.

Notice

the pyramid at the center of the mesh grate, with an air outlet in the

center. It is designed to prevent ash clogging from the

pellets.

Checking

the combustion with a Testo. It was very clean, with very low CO.

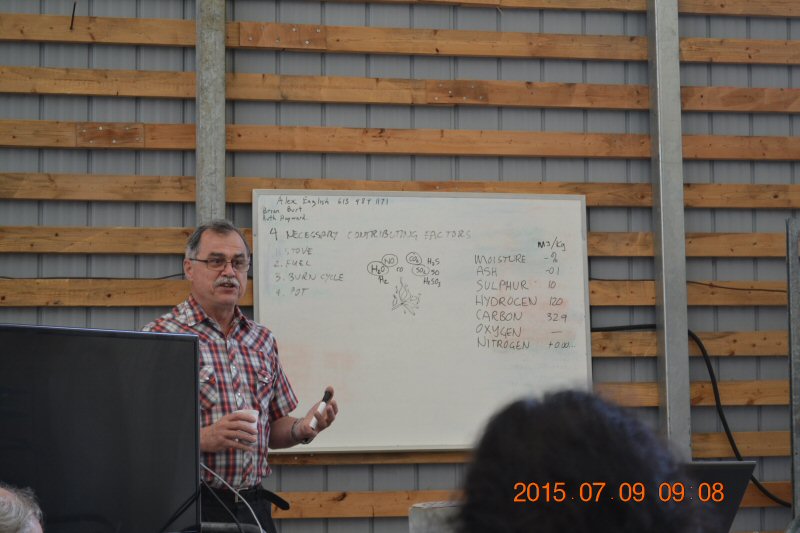

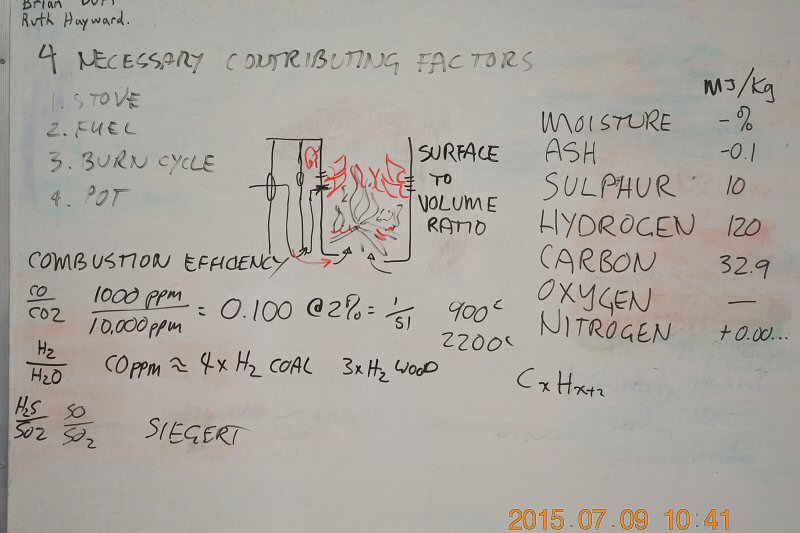

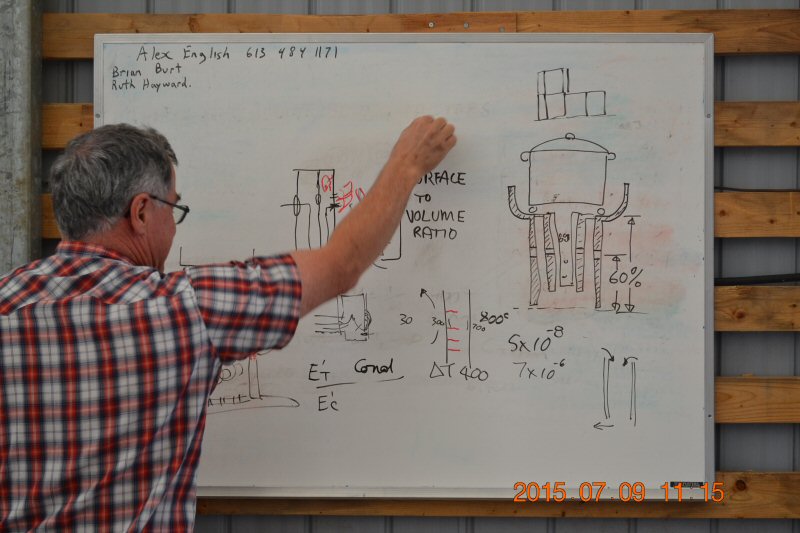

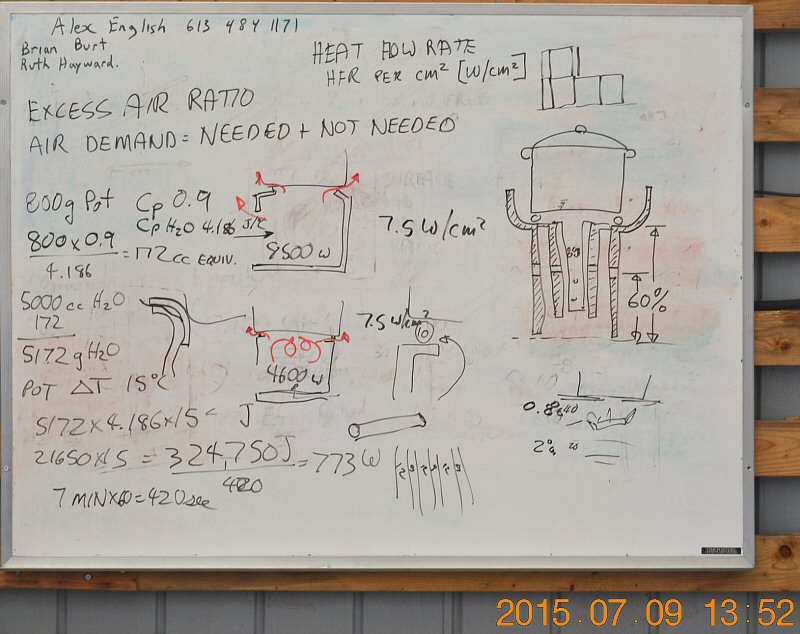

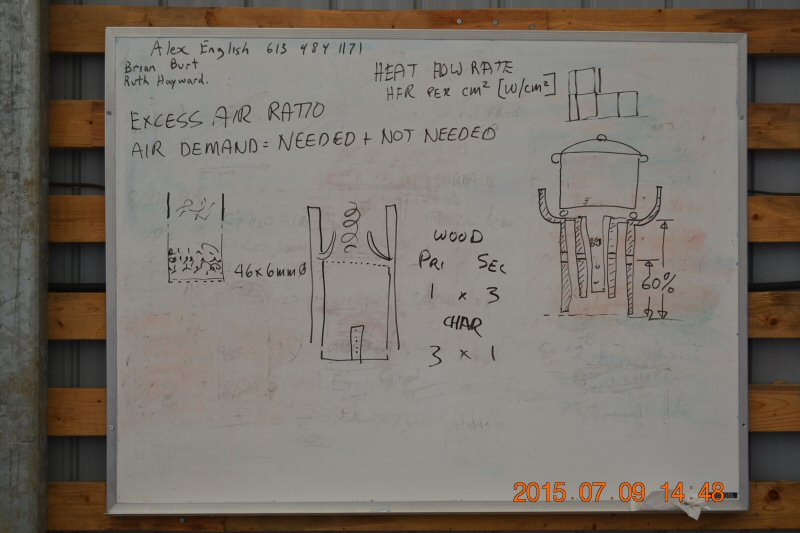

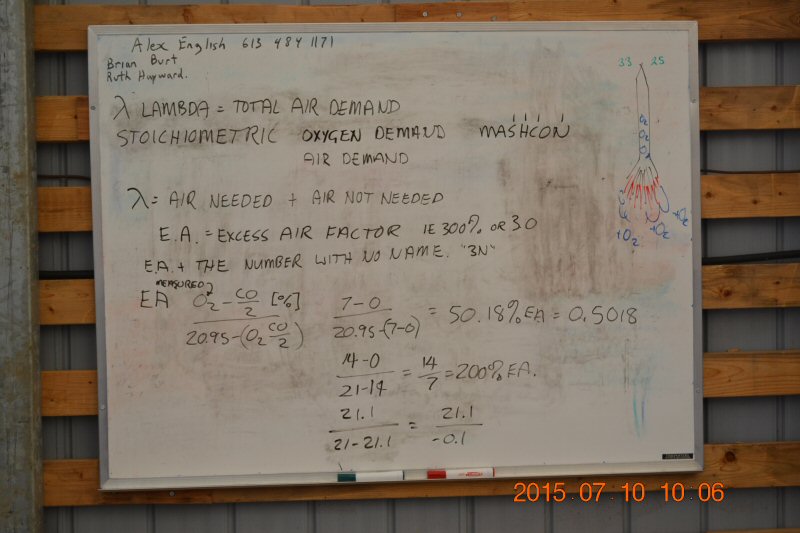

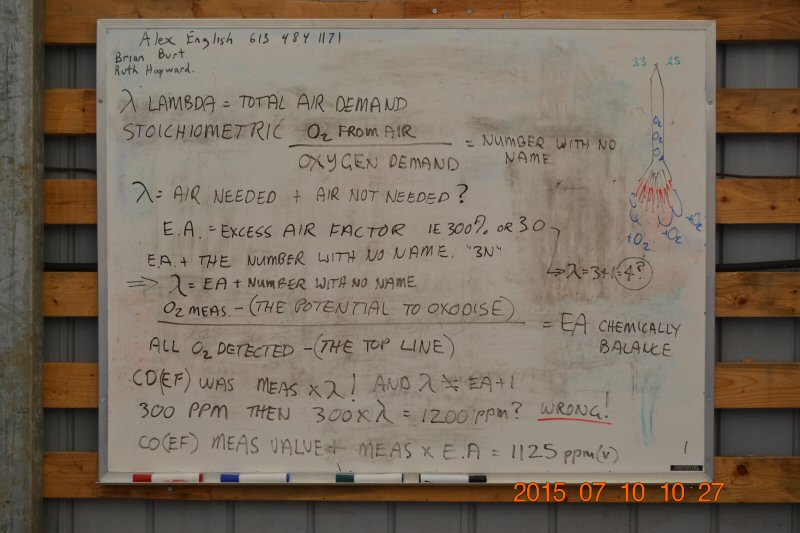

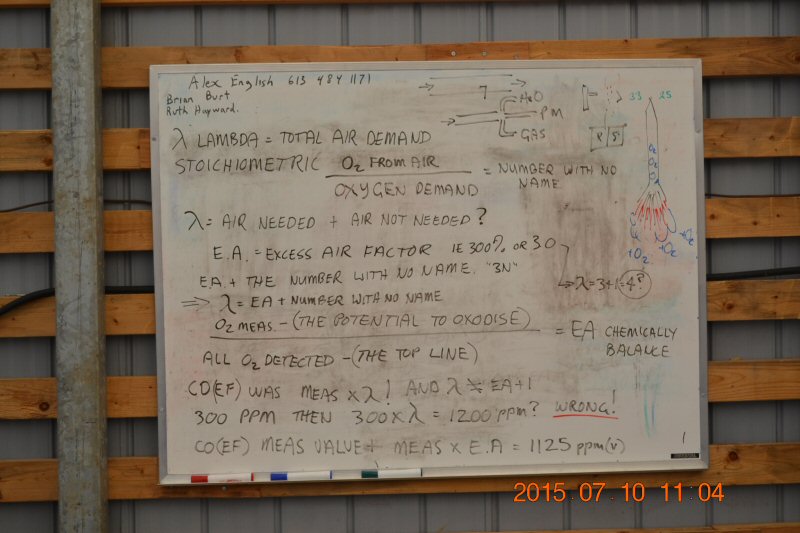

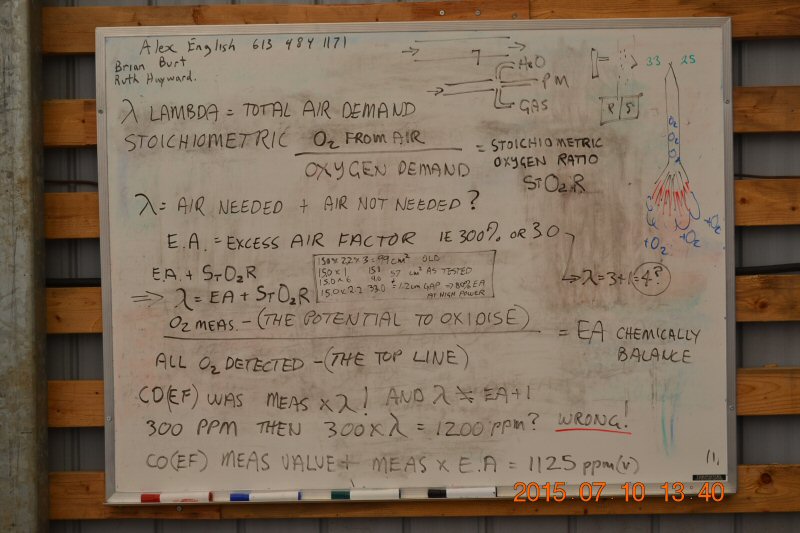

Crispin

presented results for the first time from very recent research, indicating

significant error in how

emission analyzers have calculated excess

air ratios up to now, which induces corresponding errors in reported

emissions and efficiency calculations.

Wood

is 40% oxygen, and since this is much higher compared to other fuels, and has no

associated nitrogen, this is can be

a significant source of error when

using conventional excess air calculations intended for other fuels at steady state.

Alex

gave us a tour of his chip burning operation. This building is normally

filled with fuel, and he is showing us the automated

fuel

conveyor system that he developed and built. An auger has sensors that

allow it to detect where the fuel pile is, and orient itself

to

convey chips to a conveyor trough.

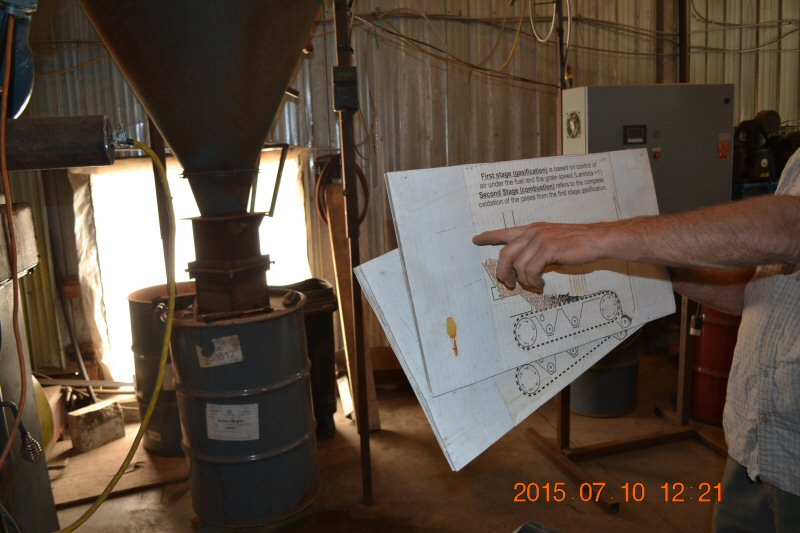

The

PLC control system for the boiler.

The

moving chain grate.

The

boiler can be used to make biochar, by closing the primary air supply.

Four

auger at the end are ganged in opposite directions, and feed the chips

into the fire chamber.

A

prototype biochar takeoff. The square duct contains an airtight auger,

that drops off the biochar into a drum.

Biochar

in a drum.

Bagged

biochar.

One

of the participants, Rebecca Vermeer, is originally from Indonesia and

does stove work

there. Here we have her clay stove

set up underneath an improvised

hood using a steel drum. Note the hose from the Wohler sampler to the

blue drum hood.

Rebecca and Nathan watch the real time data on her stove.

This

page was last updated on October 4, 2016

This page was created on July 11, 2015

Back

to: